After two years of development, TSI has successfully completed its participation in the SOST-INT Project, a strategic initiative under the PERTE Naval programme, funded by the European Union through the Recovery, Transformation and Resilience Plan (PRTR).

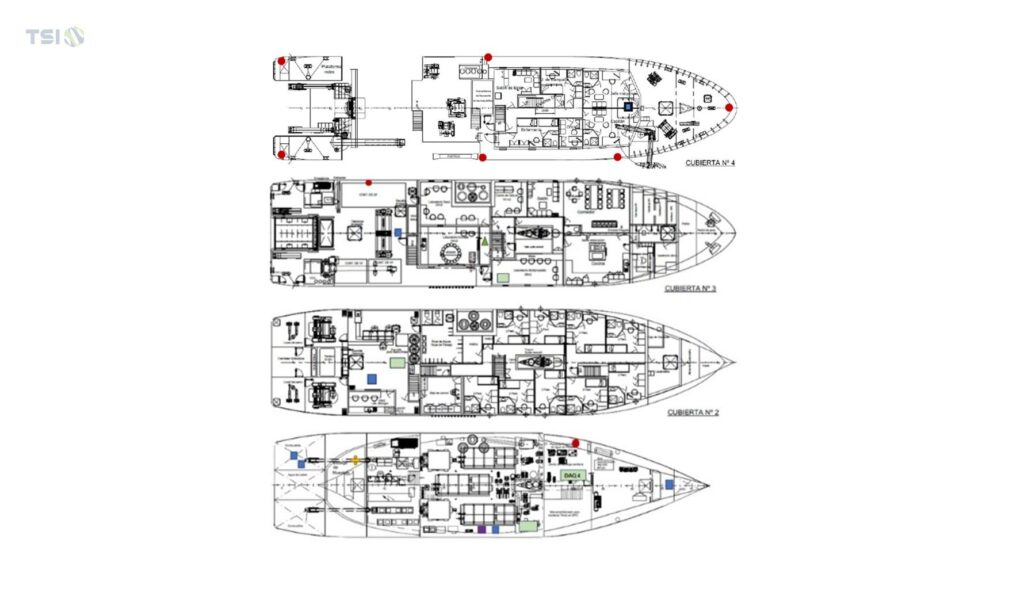

The SOST-INT Project is one of the core projects within the INNCODIS flagship initiative, aimed at developing an innovative industrial ecosystem to support a competitive, diversified and sustainable naval sector. These tests were carried out on the oceanographic vessel Ramón de Margalef.

TSI’s Role in the SOST-INT Project

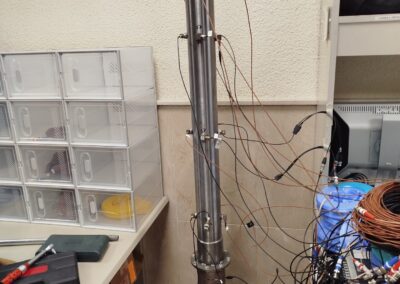

Structural sensing and data acquisition system.

At TSI, we were responsible for the design and implementation of the structural sensing and data acquisition system, focused on the structural and dynamic monitoring of ships under operational conditions.

Our scope of work included:

-

Structural and dynamic instrumentation, aimed at monitoring the structural health of the vessel during service.

-

Distributed data acquisition architectures, deployed in representative areas of the ship, including technical spaces such as the engine room.

-

Communication systems specifically designed for naval environments, ensuring data continuity under complex operational scenarios.

The system was developed in accordance with the applicable standards and requirements of Classification Societies, addressing both the structural and operational needs of the vessel.

Monitored Structural and Dynamic Variables

The project focused on a set of critical structural and dynamic variables, including:

-

Global ship motions, modelled considering the vessel as a beam.

-

Vibration levels in structurally sensitive areas.

-

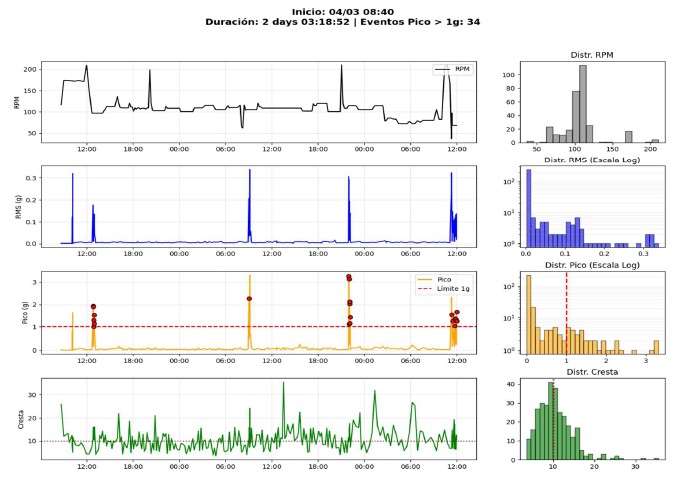

Dynamic phenomena associated with bow slamming impacts.

-

Localised and lateral loads acting on different areas of the ship.

From Monitoring to Condition-Based Maintenance (CBM)

Advanced signal processing.

Data acquisition and processing logics were implemented using LabVIEW, incorporating selective data storage strategies that allow only structurally and operationally relevant events to be recorded.

Advanced signal processing capabilities included:

-

Digital filtering, numerical integration and spectral analysis.

-

Dedicated algorithms for the detection of significant dynamic phenomena.

-

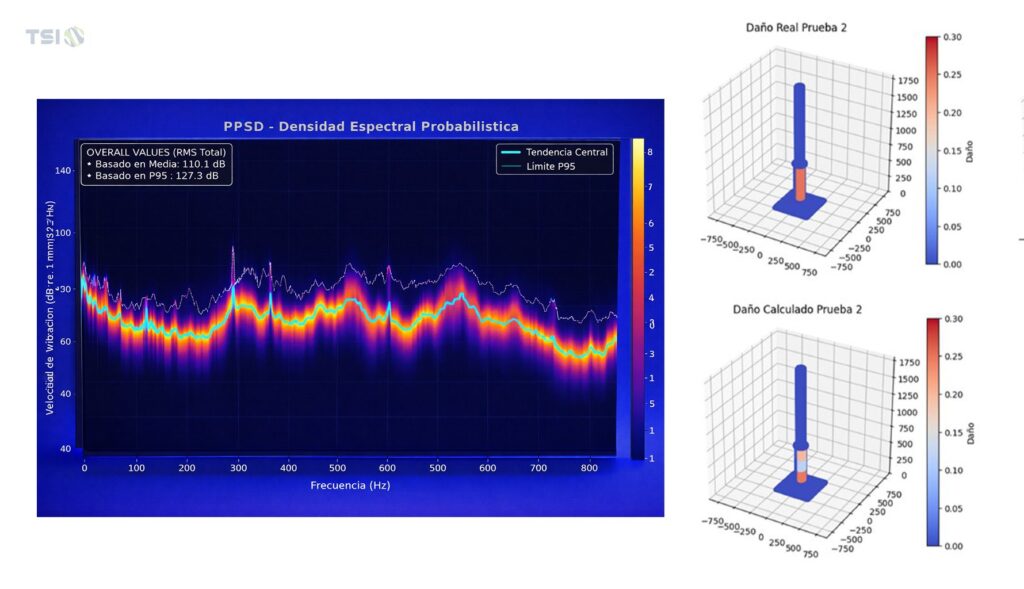

Calculation of severity parameters such as RMS, peak value, crest factor, and Probabilistic Power Spectral Density (PPSD).

Implemented CBM Strategies

The results obtained enable the deployment of a Condition-Based Maintenance (CBM) strategy at two complementary levels:

-

Direct CBM, focused on operational monitoring and real-time detection of significant events through indicators and alarms.

-

Advanced CBM, based on the use of onboard sensor data as inputs to structural models, enabling the analysis of the ship’s global structural behaviour and lifecycle performance.

The overall objective of the project has been the design and development of advanced digital tools for intelligent ship sustainment, integrating structural sensing, advanced signal processing and structural models, all validated under representative operational conditions.

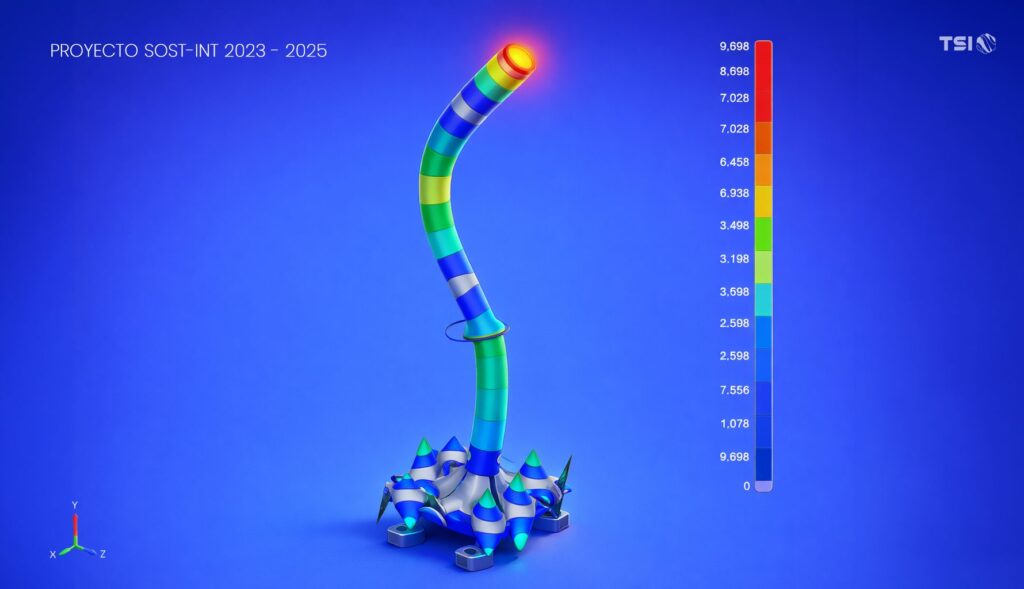

Structural Models and Virtual Sensing

Integration of FEM models with experimental data.

As part of the project, strategies for feeding Finite Element Method (FEM) structural models were developed, aimed at inverse analysis and laying the groundwork for future advanced CBM methodologies.

Based on sensor measurements, dedicated Python-based APIs were implemented to transfer relevant information to the FEM model, developed using FEMAP, enabling advanced structural analysis techniques.

This approach allows:

-

Feeding FEM models with real experimental data.

-

Applying Model Updating techniques, adjusting mechanical properties to align the model with the actual structural behaviour.

-

Implementing Virtual Sensing techniques, based on modal expansion, to identify impacted or loaded areas and reconstruct the structural state in non-instrumented zones.

Sensor data therefore enables the progressive refinement of the FEM model, providing an advanced view of structural behaviour and establishing a robust basis for future analyses of fatigue phenomena and other structural degradation mechanisms, once applied to full-scale ship models.

System Validation and Methodological Advances

The project has defined and validated a methodological framework for the integration of structural sensing systems with numerical models, paving the way for future applications on real vessels.

The developed methodologies allow FEM models to be fed with experimental data, enabling the application of Model Updating and Virtual Sensing techniques for advanced structural behaviour analysis.

This approach opens the door to:

-

Identifying different structural excitation mechanisms.

-

Assessing the global structural condition of the vessel under varying operational conditions.

-

Reducing the need for extensive instrumentation across the entire structure.

A Project That Sets the Direction for Naval R&D

The SOST-INT Project represents a significant step forward in the application of structural health monitoring, advanced signal processing and condition-based maintenance to naval sustainment.

The work carried out has validated a methodological approach in which real ship instrumentation feeds FEM structural models, enabling the application of advanced CBM, Model Updating and Virtual Sensing techniques to analyse structural behaviour and its potential evolution in service.

This approach lays the foundations for future solutions focused on anticipating structural degradation mechanisms, optimising maintenance strategies, and improving decision-making throughout the ship lifecycle.

Industrial Consortium

The SOST-INT Project was developed by an industrial consortium comprising Navantia, Future Space, Cedar Bay Ibérica and TSI, within the framework of the PERTE Naval programme.

TSI and Innovation in Naval Engineering

At TSI, we continue to invest in R&D projects that transform data into actionable knowledge and engineering into real value for the naval sector.

Discover more projects in our R&D section, and explore our full range of engineering services and specialised training programmes.

👉 Don’t forget to leave a comment if you enjoyed this article or if you have any questions.