Instrumentation | Wilcoxon

Leaders in Engineering Solutions

WILCOXON SENSING TECHNOLOGIES is a leading supplier for high performance vibration monitoring and sensing solutions. Their top quality vibration sensors and accessories are trusted by OEMs, major manufacturers, and important organizations around the world. Wilcoxon accelerometers, 4-20 mA sensors, transmitters and instrumentation provide accurate and reliable vibration measurements for a wide range of markets and demanding applications.

New in | Sensor 883M | Vibration and Temperature

Looking to improve the reliability of your equipment and reduce unplanned maintenance? Discover the Wilcoxon 883M smart sensor, the latest innovation in condition monitoring for harsh industrial environments. This high-performance triaxial accelerometer provides up to 52 real-time vibration and temperature metrics, enabling accurate predictive analysis and faster decision making.

Perfect for monitoring rotating equipment in demanding environments: power generation, marine, oil & gas and key processes.

SENSOR 883M

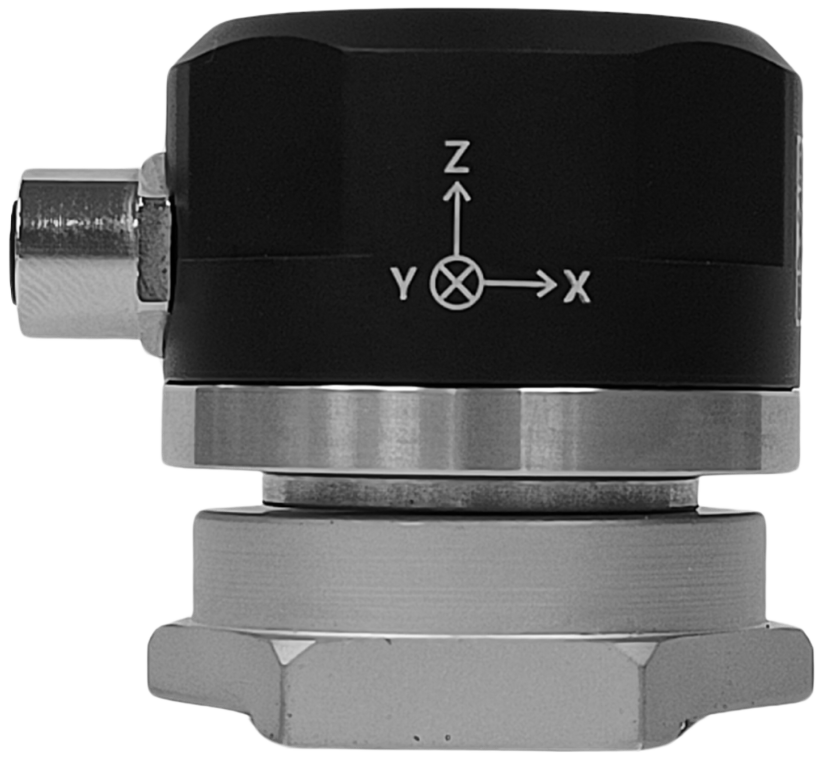

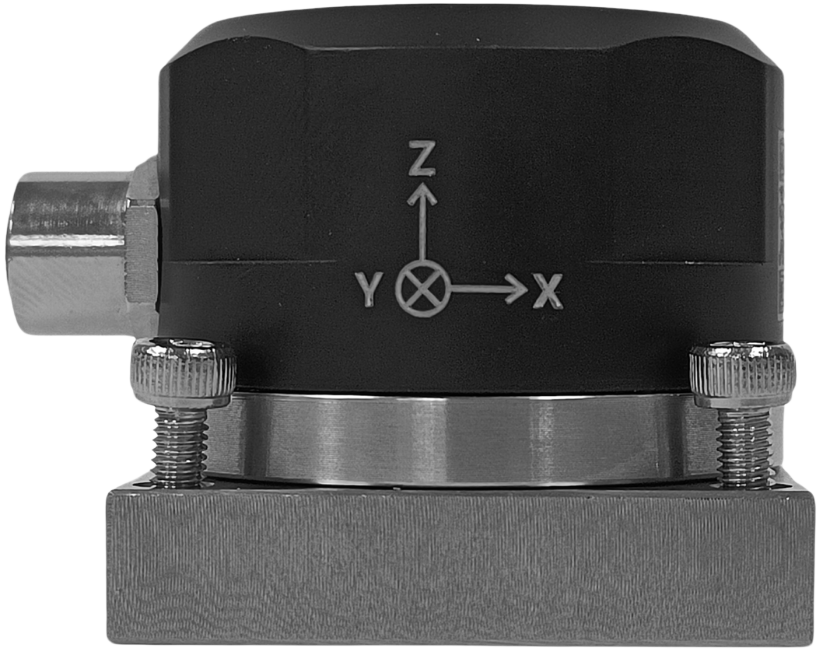

Screw mount kit

883M-SMA

Magnet mount kit

883M-MMA

Wilcoxon | SENSORS | Vibration Sensors IEPE

Wilcoxon Sensing Systems has a wide selection of high quality, long-lasting accelerometers to monitor vibration, found on rotating industrial machinery including motors, fans, pumps, gearboxes, blowers, machine tool spindles, compressors, chillers, rollers, and mixers. Maintenance and reliability professionals use Wilcoxon accelerometers for preventative maintenance and condition based monitoring.

General Purpose Sensors

ID

736T, 786C, 786B-10, 793-10, 766, 726T, 726, 746, 786ª, 780ª, 780B, 780C, 786F, 787A, 787B

High Frequency

ID

997-M4, 736T, 712F, 997, 712F-M4

Low Frequency

ID

731A, 786LF, 731-207, 786-500, 786-500-D2, 799LF, 799M, HV201LF-500, HV100LF-500

High Temperature

ID

HT786A, HT787A, HT780A, 793-6, 797-6

Hazardour Area IEPE

ID

786A-IS, 786A-M12-IS, 786-500-IS, 786-500-D2, 786F-IS, 786f-D2, 787A-IS, 787A-D2, 780ª-D2

Dual: Vibration & Temperature

ID

786T, 787T, 786T-IS, 786T-D2

Triaxial

ID

993B-7-M12, 993B-7, 993B-6, 993B-5, 993A-5, 993ª, 993B-7-33

Velocity

ID

793V, 797V, 793VR, 793V100-5, 793V-5, 893V

High Voltage Isolation

ID

HV201, HV100, HV201LF-500, HV100LF-500

Radiation – Resistant

ID

793R, 797R, 793VR.

Low-Power, Low-Voltage

ID

LPA100T, LPA100T-D2

Wilcoxon | SENSORS | Vibration Sensors (4-20 mA)

Wilcoxon offers a broad selection of 4-20 mA vibration sensors. Our 4-20 mA sensors are an accelerometer and vibration transmitter combined in one rugged industrial housing. This sensors provide a 4-20 mA output signal proportional to the overall vibration level. The 4-20 mA output is commonly accepted by process control systems such as a PLC, DCS or SCADA system for cost-effective continuous vibration monitoring.

Acceleration

ID

PC420ATP-20, PC420AR-20-DA, PC420-10-DA, PC420AR-05, PC420AR-20

Velocity

ID

PCC421VP-10-R6, PCC423VP-10-J9T2A, PCC421AR-05-M12-4, PC420VR-05, PC420VP-05

Displacement

ID

PC420DPP-40

Hazardous area

ID

PC420AP-05-EX, PC420VP-30-EX, PC420VP-30-IS, PC420VP-50-EX, PC420VR-20-IS

HASRT-enabled

ID

PCH420V-R6, PCH420V-M12, PCH420V-R6-HZ, PCH420V-M12-HZ

Wilcoxon | SENSORS | Vibration Sensors (HART)

The first smart HART vibration sensor for industrial environments. Now, it’s easier and more convenient to analyze vibration data on your critical rotating equipment using existing HART networks as part of your process automation, condition monitoring and machinery diagnostics application. Take advantage of our smart HART enabled sensors that provide many advantages including the ability to more accurately identify machine faults like unbalance, alignment, looseness and bearing wear condition.

PCH420V-R6

PCH420V-M12

PCH420V-R6-HZ

Wilcoxon | TRANSMITTERS | IT MODULES

The IT Series Vibration Transmitters allow for an IEPE acceleration, velocity, or temperature measurement to be converted into two separate 4-20 mA outputs. Field configuration, MODBUS communication, and relay mapping are some of the features available with these new intelligent transmitters.

iT150

Description

Vibration transmitter, IEPE accelerometer, velocity sensor or dual output (vibration + temperature) input, 4-20 mA outputs, pre-configured full-scale range, pre-configured frequency bandwidth.

iT300

Description

The iT300 Series of configurable transmitter modules perform acquisition and processing of dynamic vibration signals. The transmitters are field configurable. Configurable parameters include: input signal type, measurement bandwidth, detector type, output type, English or metric measurement units, 4-20 mA driving source and full-scale range.

iT301

Description

The iT301 Series of configurable transmitter modules perform acquisition and processing of dynamic vibration signals. The transmitters are field configurable. Configurable parameters include: input signal type, measurement bandwidth, detector type, output type, English or metric measurement units, 4-20 mA driving source and full-scale range.

Wilcoxon | VIBRATION METER

Wilcoxon´s vibration meter and shakers, help to detect problems in the machinery before it fails and cause damage, paralyzing the production of the plant.

MAC200

Description

Wilcoxon’s handheld vibration meter helps find machine faults before they impact operation or cause catastrophic failures. The MAC200 can increase productivity and lower maintenance costs by identifying vibration problems and bearing conditions in early and late stages of failure.

MAC800

Description

Wilcoxon’s handheld vibration meter helps find machine faults before they impact operation or cause catastrophic failures. The MAC800 kits increase productivity and lower maintenance costs by identifying vibration problems including bearing conditions in early and late stages of failure. This simple, easy to use meter records, analyzes and displays vibration signals and comes with built-in band filters for unbalance, misalignment and looseness. Combined with the included DataMate software, the MAC800 can become the foundation of a plantwide condition monitoring program, supporting up to ten machine.

MAC810

Description

Wilcoxon’s handheld vibration meter helps find machine faults before they impact operation or cause catastrophic failures. The MAC800 kits increase productivity and lower maintenance costs by identifying vibration problems including bearing conditions in early and late stages of failure. The MAC810 kits increase productivity and lower maintenance costs by identifying vibration problems including bearing conditions in early and late stages of failure. This simple, easy to use meter records, analyzes and displays vibration signals and comes with built-in band filters for unbalance, misalignment and looseness. Combined with the included DataMate software, the MAC810 can become the foundation of a plantwide condition monitoring program, supporting up to ten machine. This model include an strobe light attachement and a DataMate Pro software.

MAC820

Description

Wilcoxon’s handheld vibration meter helps find machine faults before they impact operation or cause catastrophic failures. The MAC800 kits increase productivity and lower maintenance costs by identifying vibration problems including bearing conditions in early and late stages of failure. This simple, easy to use meter records, analyzes and displays vibration signals and comes with built-in band filters for unbalance, misalignment and looseness. Combined with the included DataMate software, The MAC800 can become the foundation of a plantwide condition monitoring program, supporting up to ten machine. In addition to the characteristics of its previous models, it includes a headphones with its own case.

REF2510R

Description

The ReferenceMate portable vibration reference source enables users in the field to easily verify sensor performance and the integrity of the cabling between the sensor and the online system. SENSORS

Wilcoxon | Marine Applications | HYDROPHONES

Hydrophones are underwater microphones for acoustic measurements. Wilcoxon Sensing Technologies hydrophones are built to withstand the rigors of continuous underwater exposure in both sea water and fresh water environments. Each hydrophone uses piezoelectric crystals with a built-in electronic amplifier, to boost the low level signal of pressure waves underwater signals. The output is a dynamic AC signal superimposed upon the DC Bias.

OUTPUT TYPICAL APPLICATIONS

Underwater biological studies

Ship noise studies

Pump and machinery studies

Monitoring of underwater ordinance

H505L

Description

- Designed as a small, versatile, self-amplified hydrophone for general purpose applications to a wide variety of underwater acoustic measurements.

- The internal amplifier eliminates triboelectric cable noise, connector contamination problems and the requirement for an expensive in-line amplifier.

- The hydrophone and cable entry are completely encapsulated in polyurethane. This alleviates water intrusion caused by cathodic action.

- The hydrophone and cable entry are completely encapsulated in polyurethane. This alleviates water intrusion caused by cathodic action.

- Applications for the H505L include underwater biological studies, ship noise studies, pump and machinery studies and monitoring of underwater ordnance.

- Frequency response +/- 3dB 2 to 10 KHz

- Maximum temperature 80ºC. Maximum operating depth 250 m

H601

Description

Low acceleration sensitivity hydrophone

- Extremely low acceleration sensitivity

- Hermetic seal

- Electrically shielded

- Manufactured in ISO 9001 facility

H23-130

Description

- Ultra low noise internal amplifier

- Underwater operation to 680 meters, 2230 feet, 1000 PSI

- Underwater sound measurements over the frequency range 5 Hz to 150 kHz (+6/-10 dB)

- Integral cable up to 185 ft (56 m)

- Rugged construction

- Low cost

H23-100

Description

- Ultra low noise internal amplifier

- Underwater operation to 680 meters, 2230 feet, 1000 PSI

- Underwater sound measurements over the frequency range 5 Hz to 120 kHz (+6/-10 dB)

- Integral cable up to 240 ft (73 m)

- Rugged construction

- Low cost

H23-080

Description

- Ultra low noise internal amplifier

- Underwater operation to 680 meters, 2230 feet, 1000 PSI

- Underwater sound measurements over the frequency range 5 Hz to 100 kHz (+6/-10 dB)

- Integral cable up to 300 ft (90 m)

- Rugged construction

- Low cost

Wilcoxon | Marine Applications | VECTOR SENSORS

Wilcoxon vector sensors measure the acoustic pressure and particle acceleration in three orthogonal axes. These four sensing elements are located in a single housing with a common acoustic phase center. The four channels of the vector sensor, when combined, produce a cardioid directivity pattern which provides approximately 4.8 dB improvement in the signal to noise ratio over a traditional omni-directional pressure sensor. In addition, engineering sensors are embedded within the housing and, when combined with acoustic sensors, can provide a bearing to the target.

VS-209

Description

- Three orthogonal axis accelerometers and one omnidirectional hydrophone

- Preamplifier and differential output

- Pitch and roll

- Four channel combination provides an approximately 4.8 dB improvement in signal to noise ratio

- Micro-controller with RS-485 link

- Typical applications:

- Oil and gas exploration / Marine wildlife monitoring

- Underwater acoustic research / Harbour and inlet security

- Homeland security

- Military surveillance

- Towed arrays / Stationary arrays

- Underwater monitoring stations / Son buoy

VS-301

Description

- Low frequency vector sensor

- Three orthogonal axis accelerometers and one omnidirectional hydrophone

- Sensitivity: 10 V/g (Accelerometer); -162 dB re 1.0 V/µPa (Hydrophone)

- Frequency response: 0.5 g peak (Accelerometer); 200 Pa peak (Hydrophone)

- Temperature range -10 ºC to 60 ºC

- Preamplifier and differential output

- Pitch and roll

- Four channel combination provides an approximately 4.8 dB improvement in signal to noise ratio

- Micro-controller with RS-485 link

- Typical applications:

- Oil and gas exploration / Marine wildlife monitoring

- Underwater acoustic research / Harbour and inlet security

- Homeland security

- Military surveillance

- Towed arrays / Stationary arrays

- Underwater monitoring stations / Son buoy

Wilcoxon | INDUSTRIAL APPLICATIONS

Understand the condition of your machines and assets using Wilcoxon vibration monitoring products. Known worldwide for reliability, quality and value, the wide range of Wilcoxon sensors are used for machine measurement fault detection, condition monitoring and preventive maintenance across many applications including wind turbines, pulp and paper plants, oil and gas refineries, power generation plants, underwater environments and more.

Cement

More Info

Vibration sensors improve machine reliability, so you can maximize production and avoid downtime. Keeping process and pollution control machines in top operating condition is a key objective of maintenance and reliability engineers in cement manufacturing. Early identification of mechanical problems keeps machines running and maximizes production. Vibration analysis is an important part of machinery health monitoring within any effective condition based maintenance program. Wilcoxon Sensing Technologies® vibration monitoring sensors have been used for decades by maintenance experts around the world to detect machinery problems and avoid failure. Wilcoxon products have set the industry standard since 1960. They supply sensors for all types of rotating machines.

Condition monitoring

More Info

Food and beverage

More Info

Vibration sensors improve machine reliability, so you can maximize production and minimize downtime Food and beverage manufacturing is a highly automated process, that’s why keeping machines in top operating condition is a key objective for plant maintenance and reliability engineers. Early identification of component wear and mechanical problems keeps machines running and maximizes production. Vibration analysis is an important part of machinery health monitoring within an effective preventative and condition based maintenance program. For decades, Wilcoxon Sensing Technologies® vibration monitoring sensors have been used around the world by maintenance experts to detect machinery problems, avoid failure and improve line equipment effectiveness.

Machine tool

More Info

Vibration sensors improve machine reliability, so you can maximize production and minimize downtime In demanding machining operations, the role of vibration analysis is critical. If important machine tools fail, manufacturing operations can shut down and revenue is lost. Our sensors help to avoid unexpected downtime. Maintenance and monitoring of cutting tools, CNC machines and milling play a vital role in efficient machining operations. For decades, maintenance and plant engineers have used Wilcoxon Sensing Technologies® vibration monitoring sensors to more accurately determine tool life and keep operations productive.

Metals processing

More Info

Vibration sensors improve machine reliability, so you can enhance safety and optimize productivity Plant machinery often operates in wet, dirty and dusty conditions and can be exposed to flammable or explosive hazards. Condition-based monitoring helps to maintain equipment and prevent damage. Maintenance and reliability professionals know that if machines fail, the circumstances could be dire. That’s why maintenance of process control machines and equipment reliability play a vital role in safe and efficient metals processing operations.

Mining

More Info

Vibration sensors improve machine reliability, so you can optimize productivity and enhance safety Worker safety and efficient operations depend on well-maintained machines and equipment. Environments are hazardous. Conditions are dangerous. Detection of problems on expensive machinery is a top priority. Maintenance and plant engineers rely on vibration analysis and diagnostics to analyze trends, detect problems, identify wear, prevent damage, and avoid costly repairs.

Nuclear

More Info

Oil & Gas

More Info

Vibration sensors improve machine reliability, so you can enhance safety and reduce downtime. Oil and gas operations, including offshore, petrochemical, refineries and chemical, top the list of extreme operating environments. Work conditions are hazardous. Safety is critical. Detecting and preventing unexpected oil and gas machinery and component problems is a priority. Reliability engineers and condition monitoring teams depend on vibration analysis and diagnostics to detect baseline and trend machinery health, as well as provide early warning of potential damage. Wilcoxon Sensing Technologies vibration monitoring sensors are explosion-proof, intrinsically safe and designed for high-temperature environments. They are ideal for use in hazardous areas. Sensor data provides key indicators and metrics that help to detect faults, prevent damage, extend equipment life and avoid costly repairs.

Pharmaceutical

More Info

Quality control is vital in pharmaceutical production. Plant maintenance and reliability engineers never lose sight of it, and understand the critical role of machine operations and process control to keep pharmaceutical operations running efficiently. Data from Wilcoxon Sensing Technologies sensors helps maintenance experts detect faults, prevent damage, extend equipment life, and provide early warnings to avoid failure.

Power Generation

More Info

Avoiding outages and providing constant power supply are top priorities facing power plant operators every day. To keep plants operational and lower the risk of failure, machines must be reliable. Plant maintenance teams and reliability engineers depend on vibration analysis and diagnostics to establish baseline, trend and early warning/detection of machinery health.

Pulp and paper

More Info

Every minute that your pulp and paper mill is down represents revenue loss. Maintenance and reliability engineers depend on vibration monitoring to identify mechanical problems early, keep machines running and plants operational.

Rail

More Info

Water and wastewater

More Info

Water and wastewater plants require 24/7/365 monitoring. Every minute that your plant is down could mean unsatisfied customers and regulatory fines. Maintenance, reliability engineers, and condition-monitoring experts depend on Wilcoxon Sensing Technologies sensors to keep water and wastewater plant machinery running efficiently. Its highly durable vibration analysis sensors establish baseline, trend, and early warning/detection of machinery health.

Wind power

More Info

Avoiding outages and providing constant power supply are top priorities facing power plant operators every day. To keep plants operational and lower the risk of failure, machines must be reliable. Plant maintenance teams and reliability engineers depend on vibration analysis and diagnostics to establish baseline, trend and early warning/detection of machinery health.

Defense

More Info

Vibration monitoring technologies for maritime monitoring and seismic sensing Wilcoxon Sensing Technologies products were introduced to the marketplace in 1960 by former staff members of the David Taylor Naval Research Center. In the last 50 years, their engineers have been responsible for many advances in piezoelectric accelerometers, including the development of leading-edge products, contributing industry-notable research, and forging innovative markets. From conception through production, they excel in creating and providing reliable, high performance sensing and monitoring systems for military, energy and industrial applications. Its qualified research and development staff has decades of experience and a strong track record creating and delivering products for complex monitoring systems and important programs. To discuss your requirements, and for more information on our advanced engineering products and solutions for extreme operational environments, please contact with us, infotsi@tsisl.es