The Vibration and speed experts

SpeedSys – New generation of advanced overspeed control systems with SIL certification.

ISTEC is a technology company specialising in the development of innovative and advanced solutions for industrial safety and control. Based in the Netherlands, ISTEC is dedicated to offering protection systems that meet the highest safety standards, such as SIL (Safety Integrity Level), providing state-of-the-art technology for various industrial sectors, such as energy, petrochemical, mining and transportation.

The company stands out for offering highly reliable products, such as SpeedSys over-speed control detection systems and equipment protection solutions. ISTEC focuses on integrating advanced diagnostic functions and continuous self-testing into its products, ensuring system reliability and availability without interrupting operation.

Constant innovation and commitment to quality have positioned ISTEC as a leader in the industrial safety sector, offering solutions that optimise the operation of critical systems and maximise operational efficiency. TSI has reached a collaboration agreement with ISTEC to be able to offer the best solutions at a national level in 2025.

MADE IN HOLAND

ISTEC’s SpeedSys range is designed to provide reliable and efficient protection against overspeed situations in critical machinery. These systems stand out for their compact design, high responsiveness and compliance with the main industrial safety standards (such as SIL).L).

Why choose ISTEC?

The reliability of a protection system starts with an accurate choice of hardware, but is only consolidated with a technical service to match.

At TSI, we offer expert technical support on an ongoing basis. Our goal is clear: to ensure the operational safety of rotating machinery, maximising its availability and efficiency over time.

Overspeed Protection

ISTEC offers advanced SIL-rated speed protection systems to detect overspeed and acceleration in rotating machinery. The hardware is compatible with SIL2 and SIL3 applications and comples with API 670.

ISTEC models

ISTEC’s SpeedSys range is designed to provide reliable and efficient protection against overspeed situations in critical machinery. These systems stand out for their compact design, high responsiveness and compliance with the main industrial safety standards (such as SIL).L).

OVERSPEED SYSTEM

SpeedSys 300

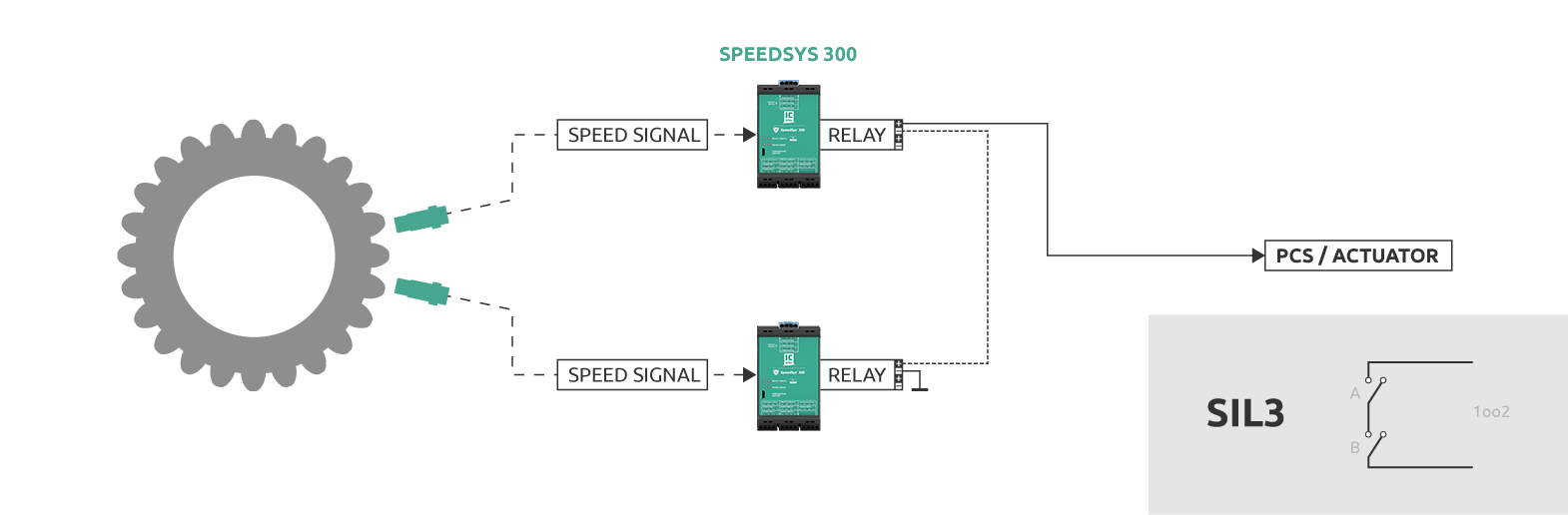

The SpeedSys 300 extends the capabilities of the 200 by incorporating additional monitoring and diagnostic functions. It is intended for environments that require detailed information on dynamic machine behaviour, combining protection with advanced monitoring in a single system.

+ Description

System features

- SIL 3 certified protection.

System response time of 8 ms.

2 safety relays + 1 analogue safety output.

Suitable for Hall effect, electromagnetic or proximity sensors.

Automated test tests.

ATEX/IECEx Zone 0,1,2 (Ex ia) isolated inputs.

Advanced self-monitoring and diagnostics.

10 year test interval.

External voting for redundant configurations.

Modbus.

Normative

- API 670

- API 612

- IEC 61508, SIL 3

OVERSPEED SYSTEM

SpeedSys 200

The SpeedSys 200 acts as an independent protection layer, with a simple, robust and highly reliable design. It offers a fast and accurate response to speed or acceleration variations, ensuring effective protection without the need for complex configurations. It is ideal for applications that require a dedicated, certified solution that is easy to integrate.

+ Description

System features

- SIL 2 certified protection.

System response time of 8 ms.

2 safety relays + 1 analogue safety output.

Suitable for Hall effect, electromagnetic or proximity sensors.

ATEX/IECEx Zone 0,1,2 (Ex ia) isolated inputs.

Advanced self-monitoring and diagnostics.

10 year test interval.

External voting for redundant configurations.

Normative

- API 670.

- API 612.

- IEC 61508, safety level 2.

ISTEC ACADEMY

Istec Academy | Technical training specialising in vibration and speed.

EASY, FAST AND RELIABLE

SpeedSys 200 is designed as a stand-alone protection layer, with a fundamentally simple and robust design. It offers fast, quality protection for speed and acceleration control. In addition, it complies with industry standards.

SpeedSys 300 is designed to combine advanced monitoring and protection functions in a single device. It integrates diagnostic, analysis and real-time monitoring capabilities, making it a complete solution for critical machinery. Complying with the most demanding industrial safety standards.

Technology that goes beyond the conventional

Speed monitoring

ISTEC offers a range of advanced speed monitoring and switching systems that provide accurate and reliable speed analysis on any rotating machine. Speed monitoring and switching systems The systems require little space and allow for low impact installations.

The tachometer series is available in four versions. In an increasingly demanding industrial environment, companies face technical and operational challenges that require highly reliable and accurate solutions.

The protection of critical rotating machinery has become a key factor in ensuring safety, avoiding unplanned downtime and complying with regulations.

| Discover the full potential of the SpeedSys Systems |