Silent Ships Solutions (S³)

Reducing underwater noise, protecting the oceans and driving naval innovation

Silent Ships Solutions (S³): a quieter future for the oceans.

In a world where reducing Underwater Radiated Noise (URN) has become a global priority, the shipping industry faces a new challenge: moving towards more sustainable, competitive and environmentally and seafarer-friendly ships.

The International Maritime Organisation (IMO), through the Revised Guidelines for the Reduction of URN (MEPC.1/Circ.906, 2023), has established a clear framework for shipowners, shipyards and operators to take effective measures to mitigate the acoustic impact of ships.

At TSI – Técnicas y Servicios de Ingeniería, we have been leading international projects in underwater acoustics, vibrations and noise for more than 45 years, offering pioneering solutions for measurement, analysis, modelling and validation in sea trials. This experience has given rise to Silent Ships Solutions (S3): TSI’s comprehensive service for the design and adaptation of ships that meet the most demanding requirements in terms of noise, vibrations and underwater radiated noise (URN).

Check out our official Poster on the impact of URN at the IMO!

What do we offer with S³?

Our comprehensive solution combines engineering and advanced technology to:

- Help the shipping industry comply with international regulations, improve competitiveness and protect the marine environment, paving the way for a quieter future in the oceans.

What does S³ mean?

S³ -Silent Ships Solutions- represents our vision for the future: an approach in which Performance, Stealth, and Sustainability come together as the three pillars of the new naval standard.

S³ is not just a service, it is a commitment:

- To shipowners, who seek competitiveness and regulatory compliance.

- To shipyards and manufacturers, who need reliable methodologies.

- To the oceans and marine life, which cannot wait any longer.

What is the URN and why is it so important?

Underwater radiated noise (URN) generated by ships has become a growing concern: in recent decades, it has increased significantly, altering the acoustic balance of the oceans and negatively affecting marine wildlife.

Aware of this problem, the International Maritime Organization (IMO) published the Revised Guidelines for the Reduction of Underwater Noise from Shipping (MEPC.1/Circ.906) in 2023, establishing a framework for action aimed at all stakeholders in the maritime sector.

These guidelines urge shipowners, shipyards, manufacturers, designers, and classification societies to implement effective solutions to reduce the acoustic impact of ships, while promoting initiatives to share practical experiences in order to enrich global knowledge in this area.

👉URN reduction is not only a technical recommendation, but also an environmental and strategic commitment for maritime transport.

«Today, new designs for any vessel must be geared toward achieving a perfect balance between performance, reduction of its acoustic signature, and detectability».

The Methodology: Control and prevention.

At TSI – Engineering Techniques and Services, we have been solving vibration and noise problems on ships for over 45 years. Our Silent Ships Solutions (S³) proposal combines experience, engineering, and technology to achieve technically validated results in two areas:

- New Vessels.

- Existing Vessels.

Specialized engineering solutions

Currently, the design of new ships must strike an optimal balance between performance and vibroacoustic behavior.

Existing Vessels

The URN database currently available for existing vessels, while invaluable from an environmental standpoint, does not allow for the precise identification of viable corrective engineering actions that would mitigate the current URN baseline in each particular case.

From a TSI perspective, it is essential to undertake a comprehensive assessment of structural noise (SBN), cavitation, the baseline radiated noise to water (URN) of each ship, and its operational performance. Only through this holistic approach is it possible to define technically and economically viable engineering solutions that enable a significant reduction in current URN while maintaining an appropriate balance with the vessel’s performance. (See more details on these activities).

In this way, we help shipowners and operators to better manage the acoustic signature.

Main activities

- Structural Noise Assessment (SBN).

- Propeller Cavitation Assessment (using our Ni-CDS system).

- URN – Underwater Radiated Noise. Baseline.

- Ship Performance: Power and Speed.

New Vessels

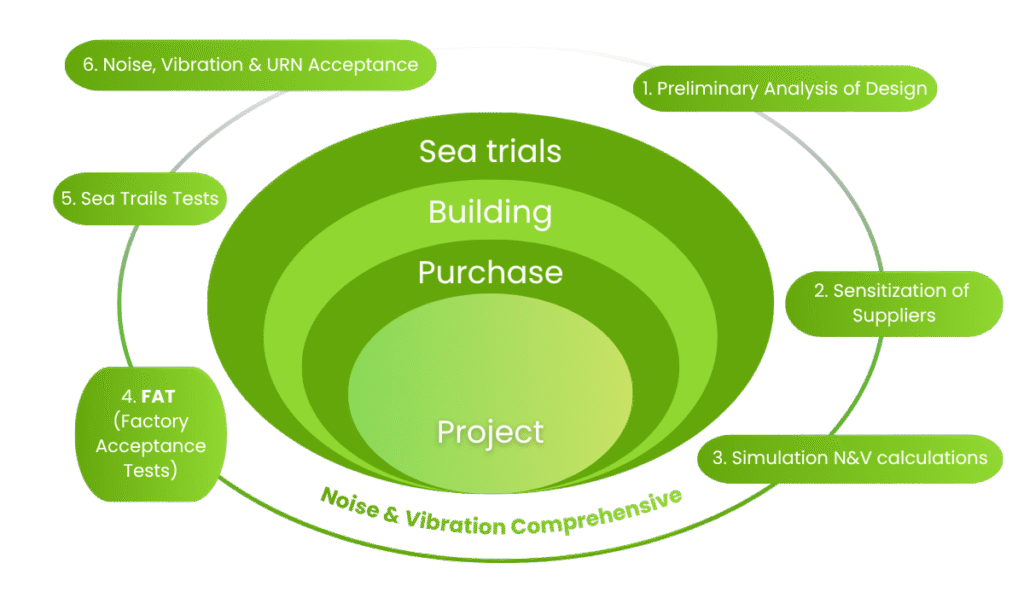

Experience has shown us that reducing radiated noise into the water (URN) in newly built ships is an achievable goal, provided that shipowners include this requirement in their contract specifications and shipyards apply the appropriate methodology to comply with it.

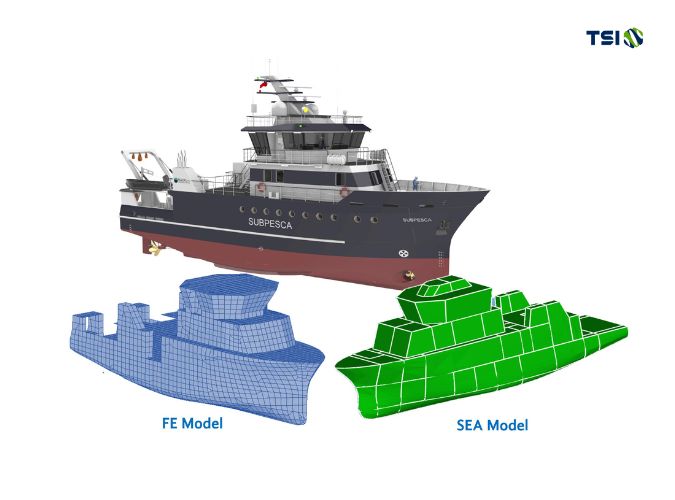

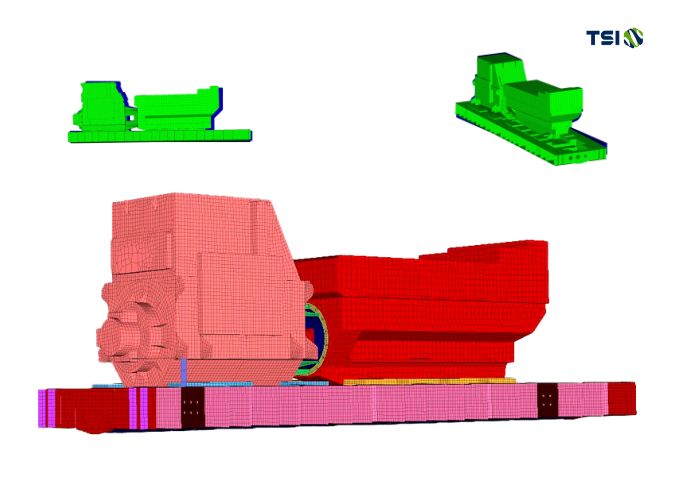

The application of our comprehensive vibration and noise management methodology to the dynamic and acoustic design of all types of ships—including specific types such as fishing research vessels (FRVs) and military vessels—using internationally recognized engineering tools (FEM, BEM, and SEA models), has enabled the development of vessels that are up to 60 dB quieter (in the case of FRVs) than conventional commercial vessels in service.

The result is quieter, more efficient, and more environmentally friendly vessels that are ready to meet the challenges of the present and the future with confidence.

Main activities

- Specification of Noise, Vibrations, and URN.

- Specific dynamic and acoustic requirements for main equipment.

- FAT – Factory Acceptance Tests for Contractual Validation.

- Solution: Comprehensive Noise and Vibration Management (N&V – CMC).

- Sea Trial Service.

New Vessels

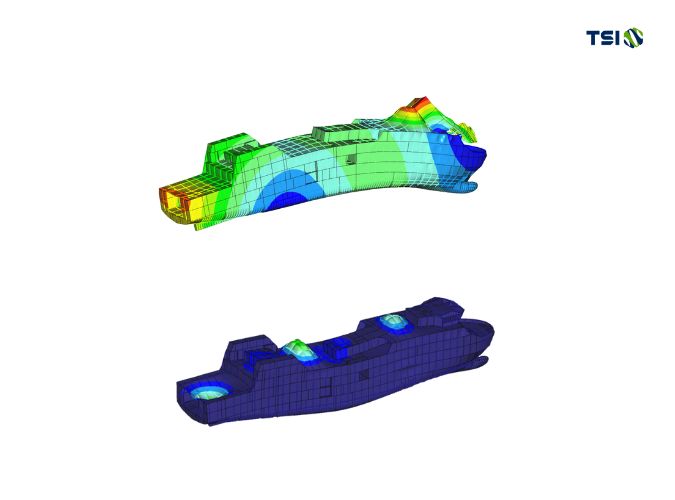

1. Structural Borne Noise Assessment

- Dynamic characterization of the machinery on board the existing vessel.

- Assessment in accordance with applicable regulations and standards.

- Recommendations for improvement.

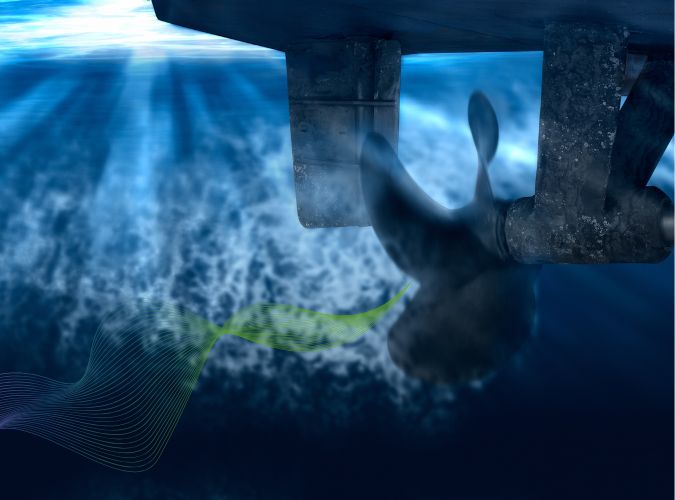

2. Propeller Cavitation Assessment (Ni-CDS)

- Actual (experimental) cavitation onset speed.

- Verification of operating profiles under cavitation conditions.

- Recommendations for selecting operating parameters that mitigate cavitation.

3. URN-Underwater Radiated Noise. Baseline Measurement

- Dynamic characterization of the machinery on board the existing vessel.

- Assessment in accordance with applicable regulations and standards.

- Recommendations for improvement.

4. Ship Performance: Power and Speed

- Dynamic characterization of the machinery on board the existing vessel.

- Assessment in accordance with applicable regulations and standards.

- Recommendations for improvement.

Existing Vessels

1. Noise, Vibration, and URN Specifications

The specialized definition in this section is essential to achieving the “Silent Ship” objective. It includes not only compliance with the limits established by regulations or the corresponding comfort notation, but also the application of the appropriate methodology to achieve the defined objectives.

2. Propeller Cavitation Assessment (Ni-CDS)

Achieving a “Silent Ship” inevitably requires controlling the main sources of noise and vibration. In this regard, defining specific dynamic and acoustic requirements for the main sources of noise and vibration is critical to meeting the project’s objectives. Buying “silence” becomes a necessity!

The correct definition of these requirements is essential for:

- Ensuring the structural integrity of the equipment supplied.

- Meeting the specified noise, vibration, and URN objectives.

- Performing an adequate dynamic and acoustic characterization of noise and vibration sources, allowing for the design of effective treatments to minimize their impact on the cost and weight of the ship.

- Applying adequate insulation to limit the transmission of noise and vibrations to the ship’s structure.

- Reducing propeller-induced excitation.

3. FAT- Factory Acceptance Tests for contractual validation.

In addition to verifying performance and structural integrity, FATs represent contractual validation of the supplier’s commitment to the project’s objectives from a dynamic and acoustic standpoint, thus contributing to the achievement of a “Silent Ship.”

4. Comprehensive Noise and Vibration Management (N&V CMC)

Specialized engineering tool for the design, analysis, and control of noise and vibrations in all phases of a shipbuilding project in compliance with Class Notations and Underwater Radiated Noise (URN) requirements.

5. Integral Sea Trials

- Comfort measurements.

- Maneuverability and operational performance.

- Machinery testing.

- Ship monitoring.

- Cavitation testing.

- Measurements of noise radiated into the water.